This article provides an overview of Apple supply chain and manufacturing process.

It examines the company's global production network and its extensive use of subcontractors, as well as their approach to product design, materials procurement, quality assurance, and environmental responsibility.

The research aims to identify areas where improvements in efficiency could be made from a supply chain perspective.

By understanding these various elements of Apple's operations, improved strategies can be developed for enhancing the overall performance of their supply chain and manufacturing processes.

READ ALSO: Apple's Organizational Structure and Management Style

- Apple's Global Production Network

- Apple's Product Design

- Materials Procurement at Apple Inc.

- Quality Assurance at Apple Inc.

- Environmental Responsibility

- Production Efficiency at Apple Inc.

- Logistics Management at Apple Inc.

- Supply Chain Optimization

- Frequently Asked Questions About Apple Supply Chain and Manufacturing Process

- Conclusion

Apple's Global Production Network

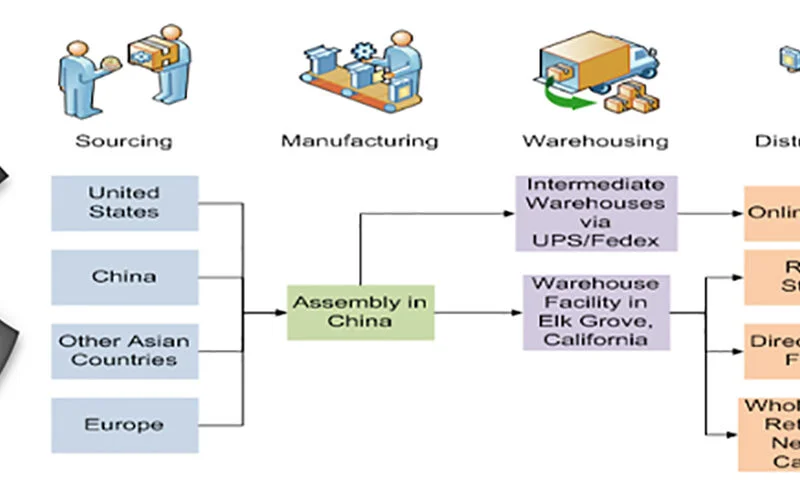

Apple Inc.'s global production network is a highly complex system that involves the coordination of hundreds of suppliers, factories, and logistics partners across multiple countries in order to bring its products to consumers worldwide.

The company sources many components from external suppliers while also leveraging internal research and development capabilities for product design.

It is critical that Apple has rigorous oversight over labor standards in its supply chain in order to ensure compliance with local laws, ethical principles, and corporate social responsibility goals.

Quality control measures are implemented at each stage of the manufacturing process as well as on finished goods before they can be shipped out for distribution.

These high standards enable Apple to deliver reliable products meeting customer expectations despite operating within a dynamic global market environment.

As part of this ongoing effort, the company continually seeks better ways to optimize both cost efficiency and quality assurance throughout its supply chain and operations management activities.

Transitioning into product design, we will explore how Apple's comprehensive approach influences innovation in today's markets.

Apple's Product Design

Product design is a critical phase of the supply chain and manufacturing process. It involves establishing product specifications, such as size, weight, shape, and cost optimization.

At this stage, manufacturers consider factors that can impact costs in order to determine suitable materials and components for their products. Furthermore, sustainability practices are taken into account during product design by evaluating how resources are used throughout the lifecycle of the product.

For example, decisions must be made on which packaging material will reduce energy consumption while also providing adequate protection against damage during transportation or storage.

The goal of this phase is to create a blueprint that ensures all quality standards are met without exceeding budget parameters. This includes anticipating potential risks associated with using certain materials or procedures that may lead to higher production costs.

Additionally, designers have to adhere to regulatory requirements set out by industry bodies and government agencies related to safety protocols and environmental considerations.

Using advanced modeling software helps streamline the entire process from concept development through prototyping so companies can adjust designs quickly based on feedback from customers or other stakeholders.

In addition to accelerating time-to-market objectives, these tools provide meaningful insight into where improvements can be made in terms of reducing costs while meeting customer demands and expectations.

Moving onto the next step, it is essential for businesses to identify appropriate sources for procuring raw materials needed for production.

READ ALSO: Game Design and Development

Materials Procurement at Apple Inc.

In the same way that a carpenter needs to begin his work with the right tools, so too must product design be followed by materials procurement.

All of the pieces of the puzzle need to fit together in order for any finished product to come together properly.

The task of acquiring supplies and materials is just as important as anything else within the supply chain process if not more so.

Materials procurement requires certain processes which help ensure cost reduction, sustainability sourcing, and quality assurance at each step along the way.

By taking into consideration these three key factors:

- Analyzing current suppliers and contracts

- Determining potential risks and opportunities

- Regularly evaluating market conditions

Procurement professionals can guarantee that their end product will meet all expectations without sacrificing resources or time.

Additionally, they are able to secure better pricing from existing vendors while also exploring newer methods such as online bidding platforms for specific projects and products.

As necessary components become available it's essential that those parts arrive on schedule and up to standard specifications; otherwise, any delays could potentially lead to longer production times or even worse – cause an entire project to fail altogether.

Without proper management of acquired materials, there would be no hope for delivering completed goods in a timely fashion nor meeting customer demand in most cases.

Thus, materials procurement plays an integral role in driving success for any business endeavor involving manufacturing or supply chain operations.

Quality Assurance at Apple Inc.

Quality assurance is an integral part of Apple's supply chain and manufacturing process. Quality control measures are implemented to ensure that products meet the required standards before they reach their final destination. These criteria include testing, inspections, evaluations, and other verification processes.

Cost reduction is also a key element in quality assurance as it helps to minimize production costs while maintaining product safety and integrity.

Apple has developed stringent international standards for its suppliers related to environmental responsibility such as energy efficiency, water stewardship, waste management, sustainable sourcing, and packaging design.

Suppliers must adhere to these regulations in order for Apple to purchase their goods or services. Moreover, Apple requires all suppliers to provide detailed reports about greenhouse gas emissions associated with their operations each year.

In addition to adhering to environmental requirements set by Apple, the company provides financial assistance through grants and investments when necessary for helping suppliers upgrade equipment or improve operational processes for more sustainability.

This serves both cost-reduction goals as well as long-term environmental protection objectives.

Moving on from this point, we can now look at how Apple approaches environmental responsibility within its own organization and across its entire global network of partners and suppliers.

Environmental Responsibility

The quality assurance process is one of the key components to ensure a successful supply chain and manufacturing process. Fundamental procedures, such as regular inspections and testing products for defects, help identify issues that may arise during production. Equally important is environmental responsibility in order to maintain sustainability goals within the organization.

Green initiatives are critical elements of any company's sustainability efforts. These measures can include utilizing energy-efficient equipment, reducing emissions from transportation vehicles, or even supporting local communities with conservation projects.

The goal is to reduce the carbon footprint associated with the production process while managing risks related to climate change and other global challenges.

Moreover, these strategies often create economic benefits by minimizing operational costs through improved efficiencies and expanding access to new markets.

Corporate social responsibility programs also play an important role in driving sustainable development throughout a company's entire supply chain network. By engaging stakeholders including suppliers, customers, employees, investors, and regulators, among others; companies have been able to develop long-term strategies for responsible sourcing materials and services that enable growth without adversely affecting people or the planet.

Companies should monitor their progress toward meeting these objectives on an ongoing basis in order to adjust plans accordingly and make necessary changes if needed.

Moving forward towards increased production efficiency requires continual effort toward improving environmental responsibility standards across all operations.

Production Efficiency at Apple Inc.

Apple's production efficiency has been a key factor in its success. Cost savings and process automation have allowed the company to remain competitive within the industry while managing complex supply chain networks.

As part of this focus on efficiency, Apple has implemented several strategies:

- Utilizing advanced technology such as artificial intelligence (AI) and robotics to streamline operations.

- Leveraging data analytics tools to track inventory levels, optimize product design processes, and identify areas for improvement.

- Developing innovative quality assurance systems that ensure products meet customer expectations and adhere to safety standards.

- Establishing global partnerships with suppliers to access new materials, reduce costs, and increase overall production capacity.

Through these initiatives, Apple is able to maximize efficiencies throughout their entire manufacturing process from initial concept through final delivery of goods at retail locations around the world.

The result is an efficient system that yields high-quality products at optimal cost levels whilst maintaining customer satisfaction and brand loyalty.

By continuing to invest in cutting-edge technologies and strategies geared towards increasing productivity, Apple looks set to maintain its position as a leader in production efficiency going forward.

Moving ahead, logistics management promises further opportunities for cost reduction by optimizing transportation costs and reducing delays due to unforeseen events such as weather or shipping errors.

Logistics Management at Apple Inc.

Logistics management involves the positioning and movement of goods from one point to another. This includes warehouse optimization for inventory efficiency, as well as delivery optimization for cost-effectiveness.

Warehouse optimization can include activities such as streamlining order fulfillment processes, improving storage utilization through automation, and reducing warehousing costs by controlling labor expenses.

Delivery optimization can involve using digital solutions to track shipments in real-time, leveraging predictive analytics to optimize routes, and utilizing third-party logistics providers to reduce shipping costs.

When it comes to supply chain management, Apple has implemented a variety of initiatives aimed at optimizing its global operations. To improve customer satisfaction levels, they have used machine learning algorithms and IoT technologies to identify areas where service could be improved or expedited.

Additionally, they have invested heavily in robotics technology to create automated warehouses that are more efficient than manual systems. Furthermore, they employ sophisticated software solutions geared towards minimizing transit times while also maximizing delivery accuracy rates.

By employing these strategies—and many others—Apple is able to achieve cost savings throughout their supply chain network while simultaneously providing customers with high-quality products and on-time deliveries.

Transitioning into the next section about ‘supply chain optimization', we will see how Apple continues to innovate in this field in order to remain competitive in today's market.

Supply Chain Optimization

Transitioning from Logistics Management to Supply Chain Optimization, the process for managing an efficient and effective supply chain is essential. Streamlining operations through optimization can reduce costs while maintaining high standards of quality and performance.

Optimizing a company's supply chain requires precise planning and strategic decision-making, taking into account all factors at hand.

First, cost reduction should be considered when optimizing a company's supply chain. This may involve reducing labor costs or making changes to existing procedures like streamlining processes, automating certain tasks, or outsourcing some services.

Additionally, reliable suppliers should be sourced in order to ensure product availability with minimal disruption of production flow.

Second, accurate forecasting based on data analysis must be conducted so that adequate inventory levels are maintained and money isn't wasted on an excess stock that won't be used or sold.

Third, demand management tools such as lead time tracking can help identify areas where additional resources may be needed or adjustments need to be made in order to meet customer orders without sacrificing quality standards or service level agreements.

Finally, developing better relationships between customers and manufacturers will improve communication channels allowing for more informed decisions about production scheduling and delivery timescales.

A successful supply chain optimization strategy requires careful consideration of multiple factors including cost reduction techniques, accurate forecasting models, appropriate demand management tools, and improved customer relations across the entire organization.

Implementing these solutions effectively can result in significant improvements both financially and operationally throughout the manufacturing process.

READ ALSO: Apple's Corporate Social Responsibility Initiatives

Frequently Asked Questions About Apple Supply Chain and Manufacturing Process

How Does Apple Ensure Ethical Labor Practices?

When considering ethical labor practices, fair wages and labor rights should be at the forefront of any business's strategy.

In order to ensure these standards are met, businesses must take proactive steps such as frequent audits of suppliers and their subcontractors.

This allows them to identify potential problems with labor conditions and address those issues before they become bigger problems.

As a result, businesses can protect workers' rights while maintaining the highest level of production quality possible.

Does Apple Outsource Its Production To Other Countries?

Outsourcing production to other countries has become increasingly popular for many companies. The benefits of outsourcing are numerous, including cost reduction and access to a larger labor pool with specialized skills.

However, there is also potential for unethical sourcing practices if the company does not prioritize ethical sourcing when selecting suppliers.

In terms of Apple's supply chain and manufacturing process, they have been known to outsource some production to other countries such as China in order to take advantage of lower costs and gain access to an international workforce.

To ensure that these processes adhere to ethical standards, Apple requires its suppliers to comply with its Supplier Code of Conduct which includes criteria related to human rights, health and safety, environmental protection, and fair working conditions.

What Type Of Renewable Energy Does Apple Use To Power Its Production Facilities?

Apple has implemented a comprehensive plan to ensure the sustainability of its facilities. This includes investments in renewable energy sources such as solar, wind, hydro, and biogas power.

Additionally, they have increased their focus on energy efficiency through initiatives like green building design, efficient lighting systems, and smart grid technology.

Furthermore, Apple is committed to sustainable sourcing by participating in programs aimed at protecting forests and establishing responsible environmental practices.

These strategies are designed to reduce carbon emissions while increasing the company's commitment to long-term sustainability goals.

How Does Apple Ensure The Traceability Of Its Supply Chain?

The traceability of a supply chain is an important component to consider for any production facility.

To ensure the necessary level of oversight and quality assurance, third-party organizations are often employed. These outside entities can offer independent evaluation and review of all components within the entire process from sourcing raw materials through final delivery.

Depending on the scope of operations, this may include factory visits and audits or reviews of related documents such as invoices and contracts.

Their findings provide invaluable insight into areas that require improvement while also verifying accuracy throughout the life-cycle management of products.

How Does Apple Use Technology To Streamline Its Production Process?

The ever-evolving digital age is bringing about a revolution in the way production processes are handled.

Smart logistics and automation technology have enabled companies to streamline their manufacturing operations, allowing them to reduce overhead costs while improving overall efficiency.

Apple has embraced this trend, utilizing automated solutions such as robotic arms and intelligent inventory management software to optimize its production process.

By employing advanced digital tools, Apple can ensure that each step of the supply chain is carried out quickly and accurately with minimal effort – something that would otherwise require significant manual labor and be prohibitively expensive.

Conclusion

The success of Apple's supply chain and manufacturing process is undeniable.

From ensuring ethical labor practices to using renewable energy sources, the company has taken great strides in becoming a leader in sustainability and efficiency.

The traceability of its supply chain ensures that customers can rest assured knowing their products come from reliable sources with quality assurance at every step along the way.

With technology playing an ever-increasing role in streamlining production, this effortless flow of materials creates an efficient and speedy process – almost as if it were running like clockwork!

While other companies may try to replicate these success stories, one thing stands out: no one quite does it like Apple.

Thank you for reading our article today! Please remember to share this article on social media to help others benefit too. It also helps us improve our algorithm and relevance to the public. Thanks for Sharring!!! Follow us on Socials: Facebook - LinkedIn - Twitter